INTRODUCTION

Industrial demolition plays a critical role in the upkeep and development of cities around the world. However, it’s also recognized as one of the most hazardous sectors to work in.

Asbestos abatement, waste removal, and hazardous material remediation — which are integral parts of industrial demolition — pose unique dangers that emphasize the critical need for safety measures for everyone involved.

Total Wrecking & Environmental, based in Buffalo, NY, believes that safety is non-negotiable and represents the gold standard of providing top tier demolition services while upholding the highest standards of safety.

SAFETY: OUR TOP PRIORITY

According to data from the Occupational Safety and Health Administration (OSHA), workplace injuries and fatalities in the construction and demolition industry have been steadily decreasing over the years, thanks to a heightened focus on safety measures and training programs. These statistics reflect the industry’s recognition of the importance of safety and the greater efforts made by companies like Total Wrecking to protect and promote the well-being of their workforce.

The nature of demolition work, including asbestos abatement, environmental remediation, and the demolition itself – demands a higher level of vigilance and precaution. We are proud of our impeccable safety record and our stringent adherence to industry standards.

How can we ensure that safety is priority in the workplace? Our abatement team is trained rigorously and certified to handle even the most challenging situations, ensuring that our employees, clients, and the environment are safeguarded throughout every project we face.

PROFESSIONALISM: A CORNERSTONE OF SUCCESS

According to industry reports, the success of demolition projects is often closely tied to the level of professionalism exhibited by the contractors involved.

A study by the National Demolition Association (NDA) found that projects executed with a strong emphasis on professionalism achieved better safety records and experienced fewer delays and cost overruns. This underscores the significance of professionalism in ensuring the smooth execution of even the most challenging projects, and highlights why should organizations prioritize what safety measures they will focus on, and how.

At Total Wrecking, safety goes hand in hand with professionalism. Our commitment to professionalism is reflected in every phase of our projects, from initial planning to final execution.

We understand that working on complex tasks such as industrial plant demolition or building demolition requires technical expertise and a disciplined approach to project management. Our team’s attention to detail, communication skills, and ability to collaborate seamlessly with clients and stakeholders exemplify the professionalism we uphold.

SETTING INDUSTRY STANDARDS

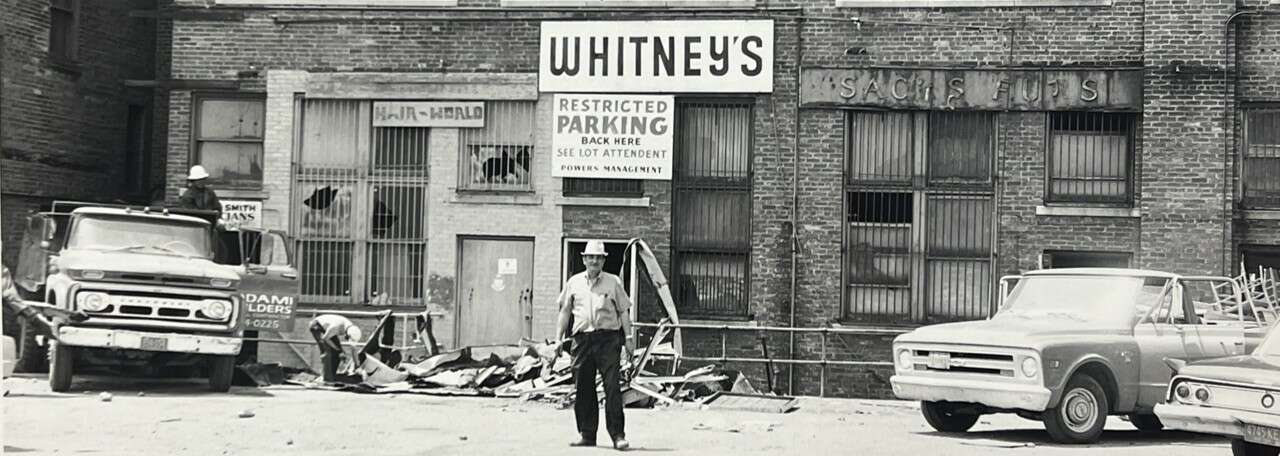

Total Wrecking’s commitment to safety and integrity has earned us a reputation as one of the most reliable and respected names in the demolition and abatement industry in the United States.

Our partnership with organizations like the National Environmental Safety Company Inc. and our affiliation with industry associations like the NDA and OSHA are a testament to our dedication to setting and upholding the highest industry standards. These collaborations ensure that our practices and services are aligned with the latest advancements in safety protocols and environmental responsibility.

With a nationwide presence that enables us to tackle projects of all sizes and complexities, our portfolio includes everything from commercial complete demolition to industrial plant decommissioning services, each executed with the same level of professionalism and safety consciousness that defines our company.

BUILDING A SAFER TOMORROW

How do you ensure safety management? By placing safety and professionalism at the forefront, and by adhering to strict safety protocols, providing comprehensive total safety training, and investing in the latest safety equipment — we contribute to the ongoing improvement of the construction and demolition sector, making it a safer and more efficient field for all.

If you need an industrial demolition company, look no further than Total Wrecking & Environmental. We have extensive experience with projects of all sizes, as demonstrated by our work at the Lakeland McIntosh Power Plant in Florida. Contact us today to get started on your next industrial demolition project.