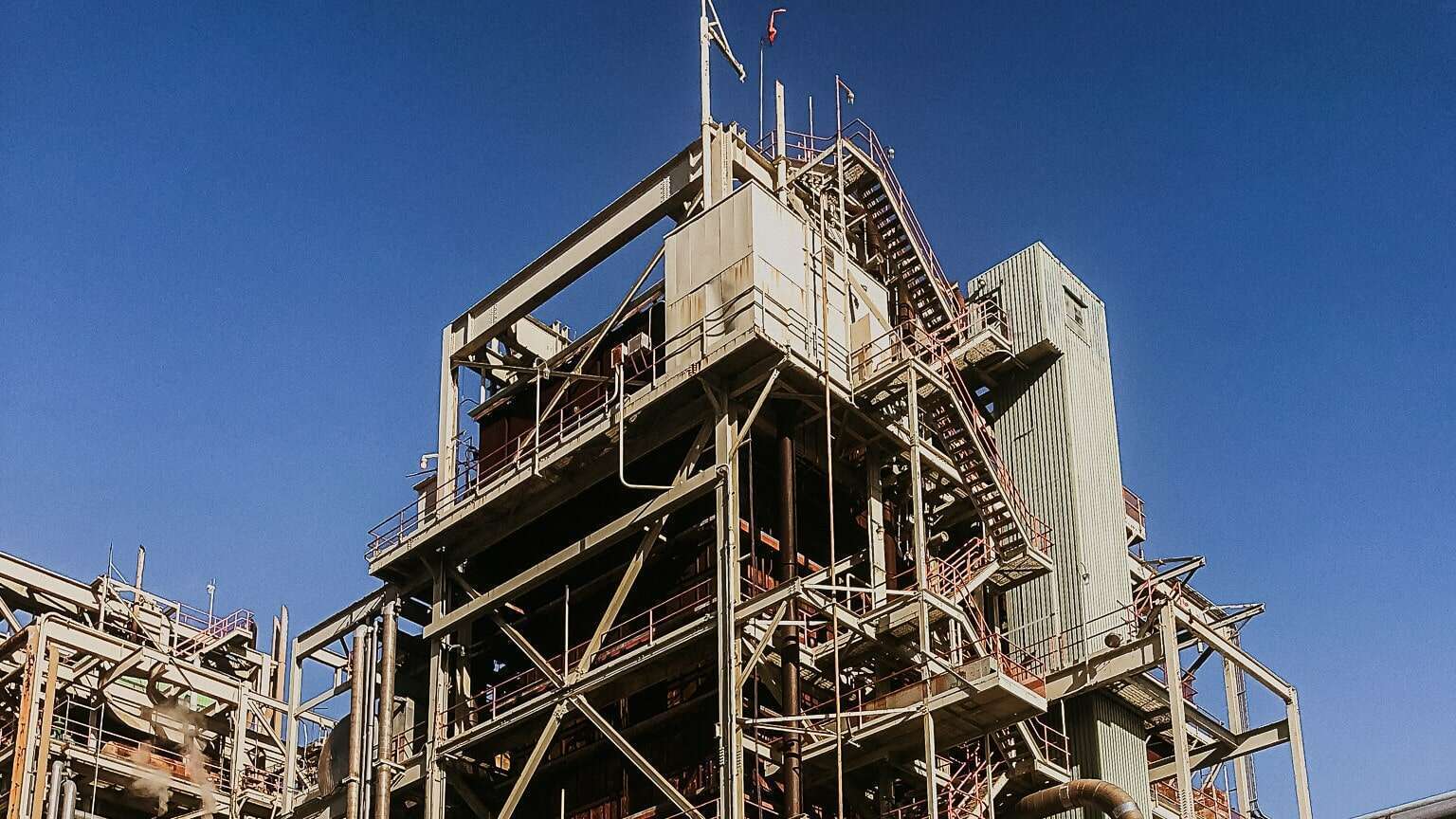

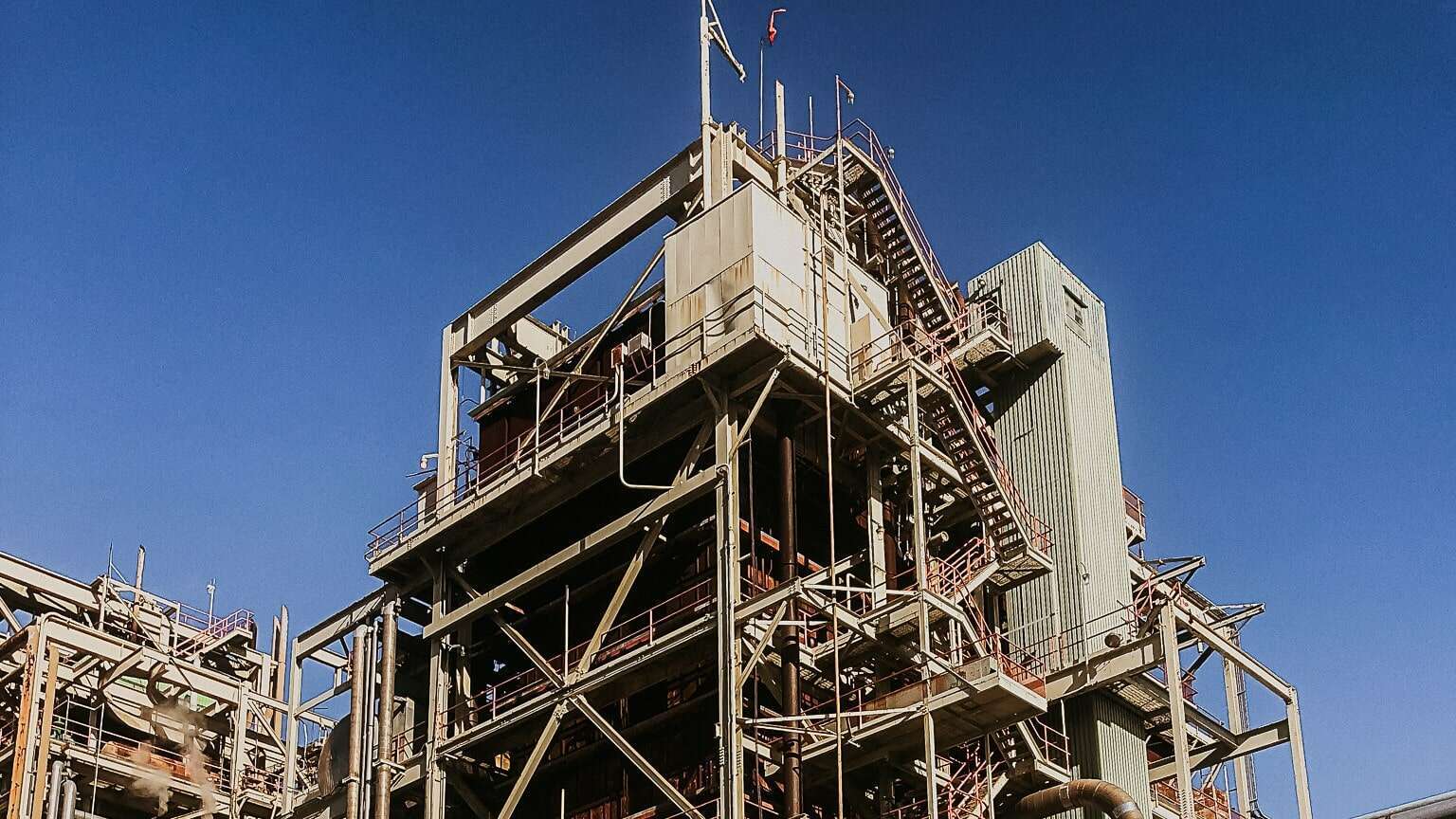

TOTAL WRECKING BEGINS WORK AT CLECO POWER PLANT IN LOUISIANA

Total Wrecking and Environmental, a nationwide industrial demolition contractor based in Buffalo, NY and led by 40-year industry veteran Frank Bodami, was recently selected to complete the controlled demolition of an aging boiler structure at the Cleco Coughlin Power Station in St. Landry, Louisiana. This $2+ million project takes place in the heart of an active power plant within an extremely sensitive and space-restricted area.

“Total Wrecking prides itself on safely managing the most complex and sensitive demolition projects in the country with unparalleled precision and expertise,” shared Total Wrecking Managing Member Frank Bodami. “Cleco Power Plant is no exception, and we’re excited to take on this challenge in St. Landry for the betterment of the whole community.”

The Cleco Coughlin Power Station consists of 3 combustion turbines (CT) and heat recovery steam generators (HRSGs) that supply steam to two repowered turbine generators. Total Wrecking and Environmental was selected to lead the demolition of Unit 6 Boiler.

This power station has been a mainstay in the St. Landry community, supplying power to local residents since 1948. The Unit 6 boiler that Total Wrecking is dismantling, along with its sister boiler, were built in the early 1960’s as natural gas-fired boilers capable of producing 115 megawatts of steam turbine power. Although refurbished in the early 2000’s to help meet growing demand, they’ve recently begun to deteriorate and require removal.

“Due to the limited space within the jobsite and the fact that all remaining structures at Cleco Power will remain active during Boiler 6’s dismantlement, Total Wrecking will employ a “top down” demolition technique to ensure safety and preserve the ongoing power plant operations,” said Nick Loncto, Project Manager for the Cleco demolition. “To further accommodate the active facility operations, Total Wrecking will also need to complete its work within predetermined outage periods.”

Total Wrecking has staffed this site with specialized workers to aid in the surgical “top down” demolition that this unique job requires. These specialized employees hold titles such as burn foreman, burners, riggers and heavy equipment and crane operators. Work will begin by carefully stitch-cutting the structure (and associated components) prior to crane mobilization, allowing for reduced crane usage and ultimately cost-savings for the client.

Once stitch cutting is complete, final cuts will be made to allow the crane to safely lift away each piece of the structure for further processing. This unique strategy was implemented as a result of restrictive site logistics and the tight, 3-month time frame that the project needs to be completed within.

Preparing for a job with this precision and complexity required a detailed review process with the plant owner, including lengthy discussions, on-site kickoff meetings with the entire project team and many collaborative reviews of the meticulous work plans. Total Wrecking has made and will continue to make every effort to prioritize safety and protect the active facility by working hand-in-hand with ownership.

The dismantling of Boiler 6 and its components also requires additional services that typically go hand in hand with a demolition project including environmental remediation in the form of minor lead abatement and the salvaging and recycling of steel (as well as small amounts of copper).

Although the close-out date for the project isn’t until late September, Total Wrecking’s efficient workflow has them eyeing a finish date closer to July/August and an off-site mobilization shortly thereafter. Whilst work is being carried out, crews will stay locally within the community they’re serving, providing positive economic benefits to the St. Landry and surrounding communities.